Mixed flow pumps that are built by a high quality pump company can add efficiency to almost any existing radial or axial pump application. This type of pump offers a higher discharge than radial pumps and a higher normal operating pressure limit than axial type pumps all through its hybrid design. The impeller inside is designed at an angle which allows it to act like a piston drive pump, but without the need for the extra draw length of the piston arm. High flow lineshaft pumps are perfect for continuous flow applications and severe duty installs. This article talks about the common applications, basic parts and design features that make up a quality, high-efficiency mixed flow pump.

The Makings of a Quality Mixed Flow Pump Design

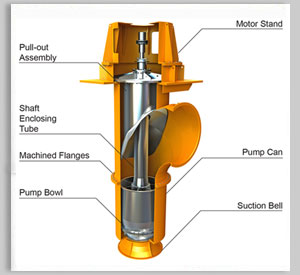

Each high quality continuous use lineshaft pump should include and be built to exacting standards. Dynamically balanced impellers, stainless steel parts like wear rings, plus the ability to remove bearings and bearing retainers must be a part of any quality pump design. Close tolerance manufacturing of flanges and internal parts and precision down to thousandths of an inch are what is included in making of a high quality, high efficiency pump system. Quality internal parts can be the difference between a pump that lasts a few years and one that lasts fifty.

Mixed flow hybrid pump designs can last for years under both severe duty and continuous use installations. The ability to remove bearings and bearing retainers allows for even further life and efficient service and is something you will want to look out for as a design feature when you go to make a purchase.

Common Applications for High Flow Mixed Pumping Systems

A quality built mixed flow pump offers a compact way (when compared to similar flow rate piston designs) to gain lift and increased velocity of a fluid which allows for a wide range of application options. This particular type of pump offers gallons per minute ratings from 2000 and 250,000, and can create total heads of water between 25 and 55 feet. You’ll commonly see a mixed flow pump in water treatment facilities, oil pumping applications, process pumping applications like sewage treatment plants and at hydroelectric facilities (to name just a few). Any severe duty applications or heavy continuous use installations will benefit from high quality mixed flow pumping systems.

Whether you are looking to replace an existing pump or you are designing a brand new pumping facility you need a high flow lineshaft designed pump that is built to work in the most severe of conditions. With so much riding on your pump, make sure you only purchase from a name you trust.